I’m also on Twitter and that stream gets updated a lot more often than this blog. Feel free to send me a message about anything you’d like to discuss.

LOL okay so b/c of Elno, find me at @krekr.bluesky.social and @krekr.ioc.exchange (Mastodon)

I’m also on Twitter and that stream gets updated a lot more often than this blog. Feel free to send me a message about anything you’d like to discuss.

LOL okay so b/c of Elno, find me at @krekr.bluesky.social and @krekr.ioc.exchange (Mastodon)

Since lots of people come looking for the Arduino Uno technical drawing, I decided to make a drawing with the main dimensions of the Wemos ESP32 as well. It’s probably the same as the D1 and other Lolin / Wemos modules. It’s based off the CAD-model by Ben Cooney on GrabCAD.

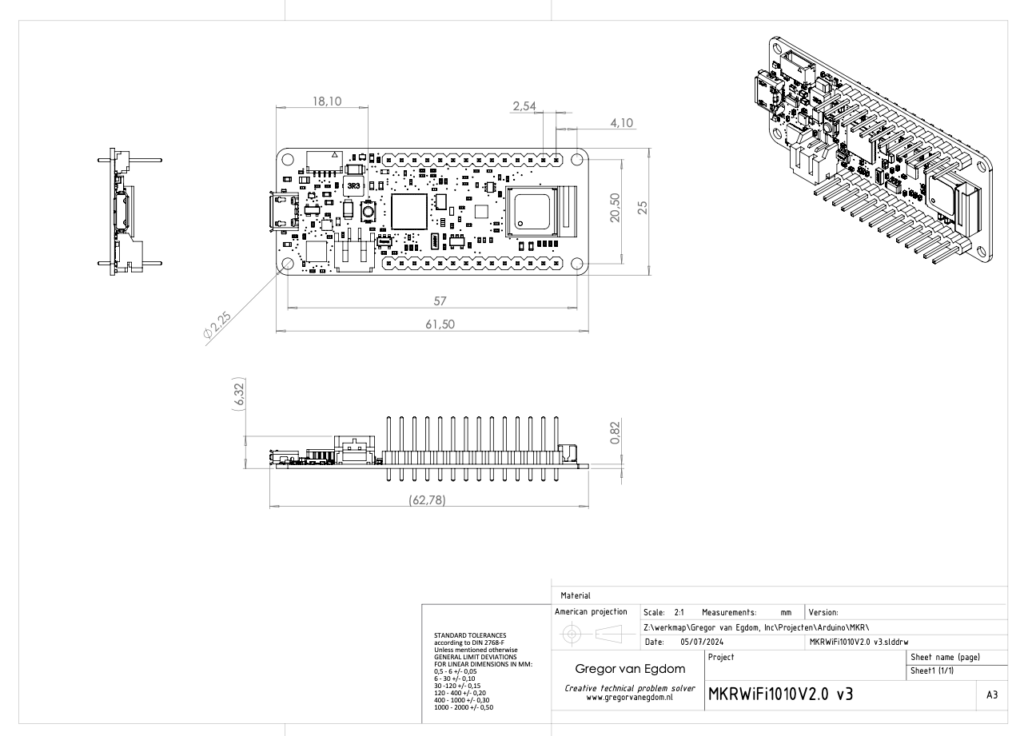

Since lots of people come looking for the Arduino Uno technical drawing, I decided to make a drawing with the main dimensions of the Arduino MKR1000 as well. It’s based off the CAD-model by Johannes Funk on GrabCAD.

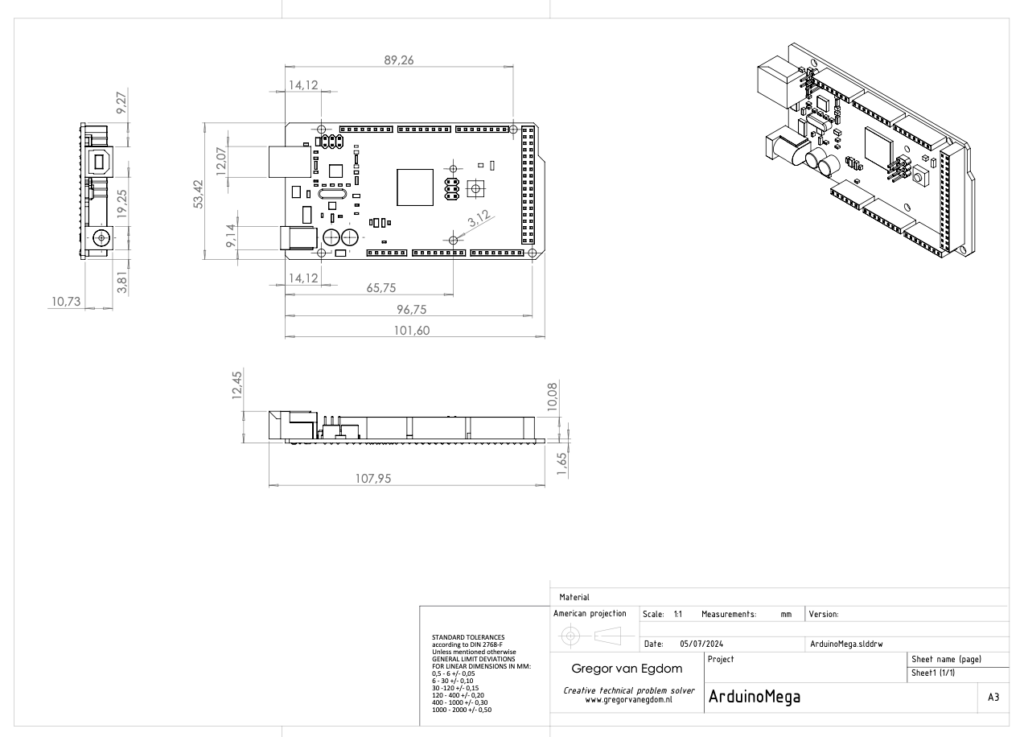

Since lots of people come looking for the Arduino Uno technical drawing, I decided to make a drawing with the main dimensions of the Arduino Mega as well. It’s based off the CAD-model by Augustine Aelevanthara on GrabCAD.

For an electro-mechanical designer, motors are a key component. Being able to move stuff in the physical world at high speed and precision makes modern products feasible. For a long time brushed, DC Motors were the only viable option, sometimes coupled to a gearbox and or encoder. Lately, more and more products began using brushless motors which also means cheaply available overstock.

You can now buy a powerful and fast brushless motor, including controller and and encoder for precision feedback for about €5 including shipping(!).

I just had to try these out. Attached is the code for open-loop control. I might implement closed-loop some time in the future as well, so this becomes even more powerful and precise.

30th of April, there was a break-in at our house and several bikes were stolen; one of mine and the others from the neighbors.

Frame number: GZ60560592

VIN: XRGA0H57A6A000281

If this bike is offered for sale to you, please get in touch with me: https://www.krekr.nl/contact/

Op 30 april is er bij ons ingebroken en zijn er meerdere fietsen gestolen; één van mij en enkele van buren. Indien deze fiets u te koop wordt aangeboden, neem dan contact met mij op: https://www.krekr.nl/contact/

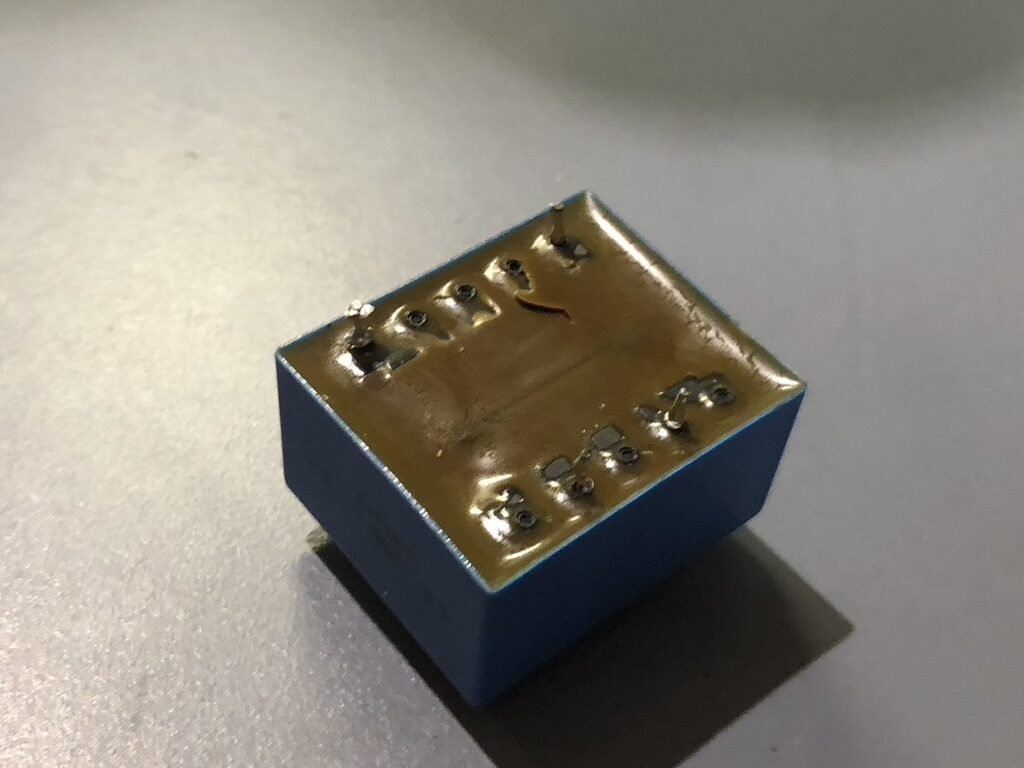

Dutch manufacturer Itho Daalderop seems to have an electronics reliability problem. I’ve now repaired 4 fans from the brand.

One common problem seems to be that the transformer on the PCB of the CVE “Centrale ventilatie eenheid” breaks. It is a very common part that can be had for about €5, e.g. at Reichelt.

The epoxy of the potting cracks. Maybe it gets too hot, maybe unfiltered spikes on the mains net cause this. Of course, these units run 24/7, but I’d advise anyone to add extra precautionary devices on any Itho appliances they might have.

Starting today, I’ll be posting teardowns of consumer electronics every month or so. These photos have been taken a long time ago, but are still relevant because most of the manufacturing technologies haven’t changed.

Resistive welds can clearly be seen, as well as an injection moulded Zamack frame. Lots of EMI gaskets and flexible circuit boards too. And a repair I made circa 2009.

I’ve has issues with my Sonos setup since installing it. It would sometimes disappear from the network, sometimes the app wouldn’t see the system etc. Today (after more than a year of disappointment) I was guided through an hour-long debugging session by the very helpful Jenny, which changed the following ASUS router settings from their defaults:

Advanced settings > LAN > IPTV > Enable multicast routing

Advanced settings > LAN > IPTV > Enable efficient multicast forwarding (IGMP Snooping)

Advanced settings > Wifi > Professional > Enable IGMP Snooping

Also, check if the firmware of the router and mesh nodes are up to date, and whether the Sonos app displays any other (old/concurrent) Wifi networks (otherwise the system might keep switching back and forth).

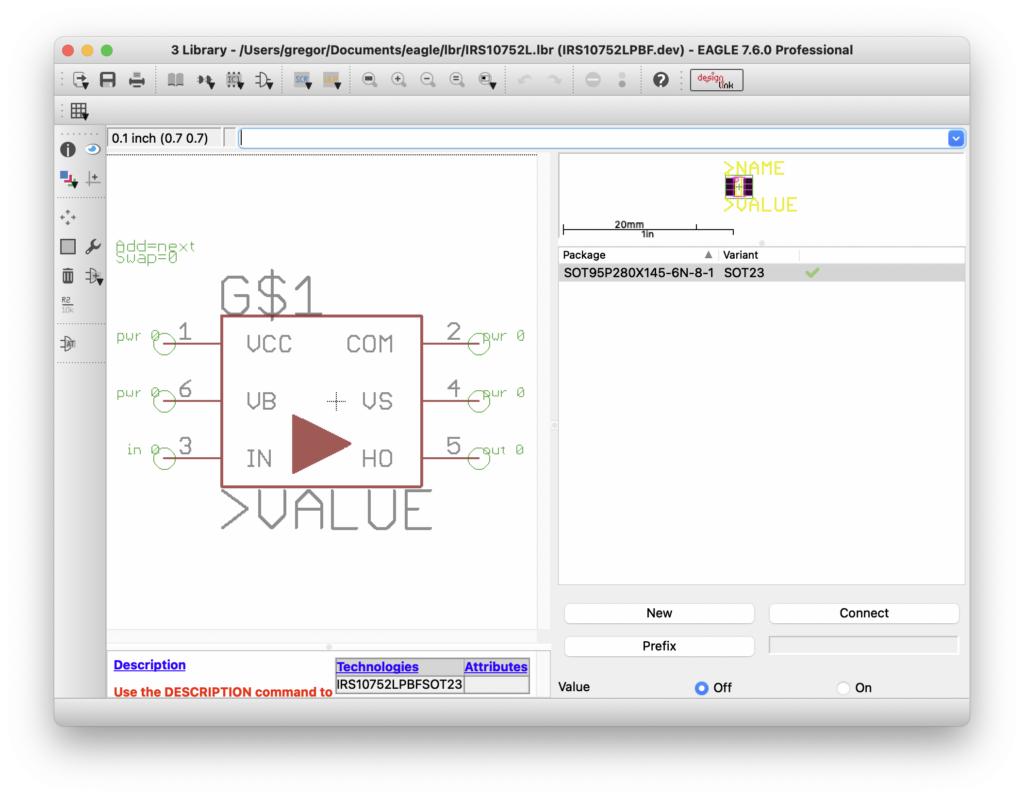

I created an integrated EAGLE library for the affordable 100V Infineon IRS10752 MOSFET Gate driver (the download from Infineon provides a package and schematic symbol, but not a ‘device’ with the right connections).

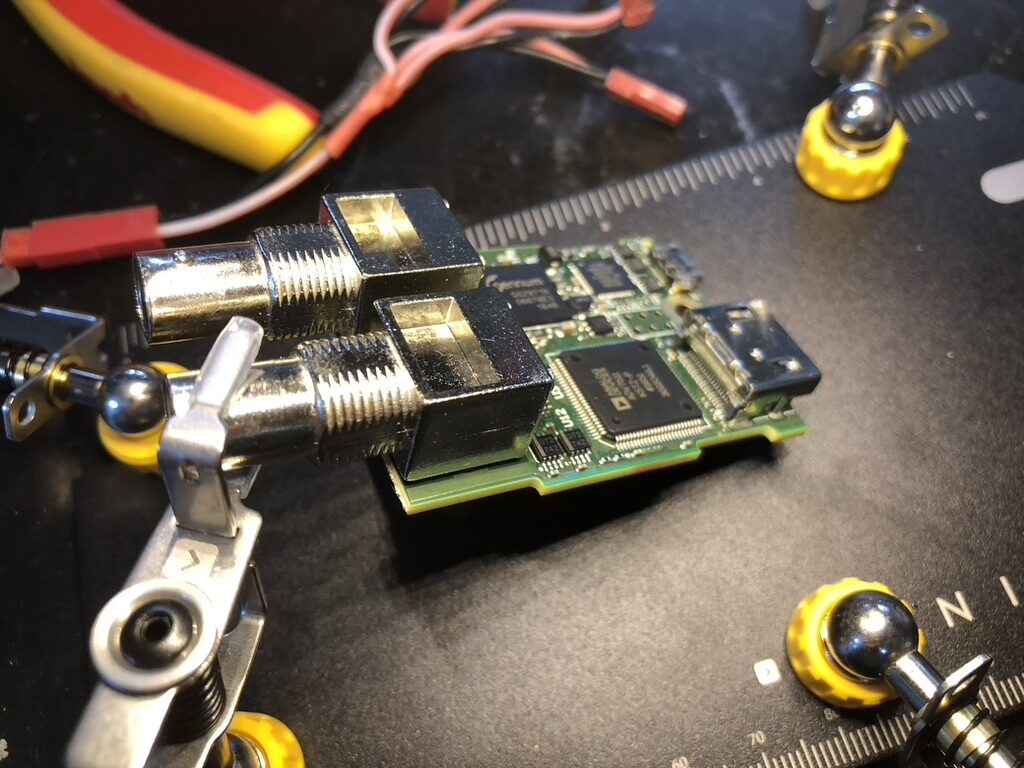

Blackmagic Design make some really awesome hardware. With some shitty flaws that means they break on lousy parts like a micro USB-connector.

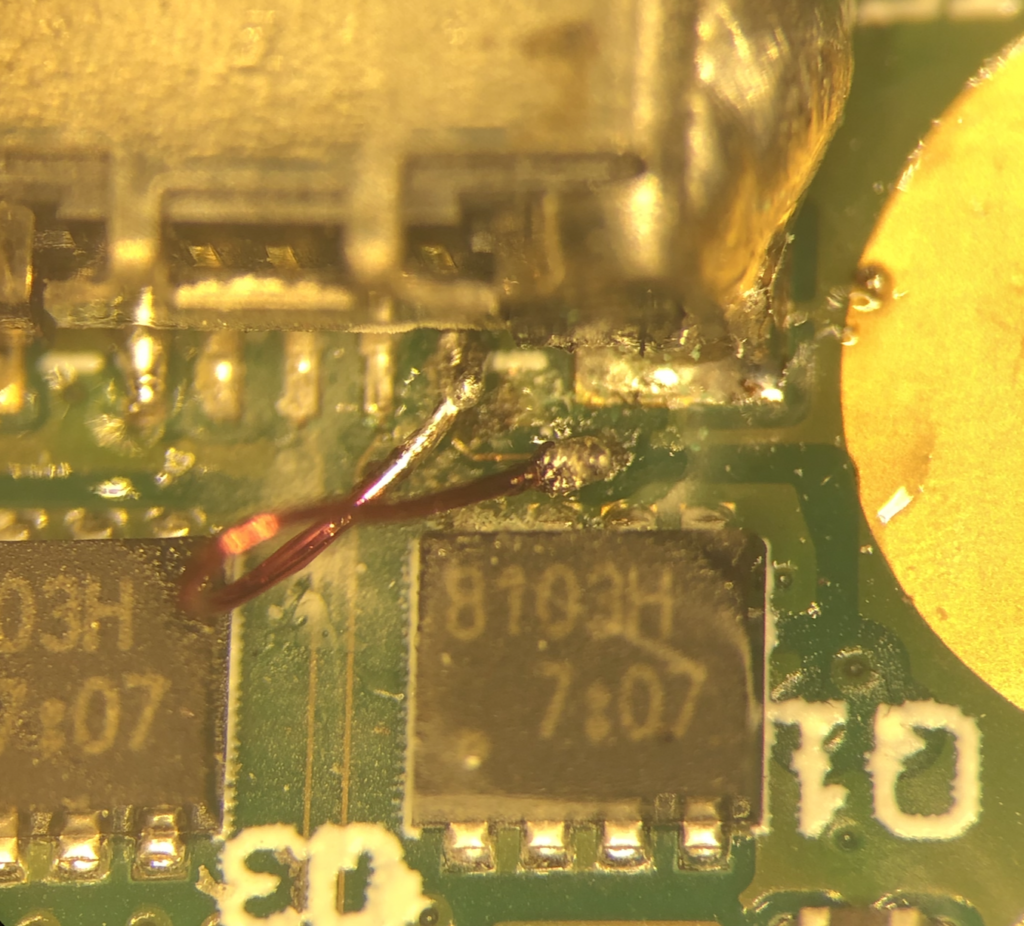

I recently got a SDI-HDMI converter that only powered on intermittedly, probably because of the micro-USB connector coming loose after a mechanical shock/snag/… accident.

The current version of these is using USB-C, which is a lot more mechanically robust. But still, if you’re using these in a production environment, you’ll probably want to tape down the wires so there is no accidental force on the connector. It’s not really a field-proof power supply connector imho, especially for the types of environment BMD’s customers operate in.

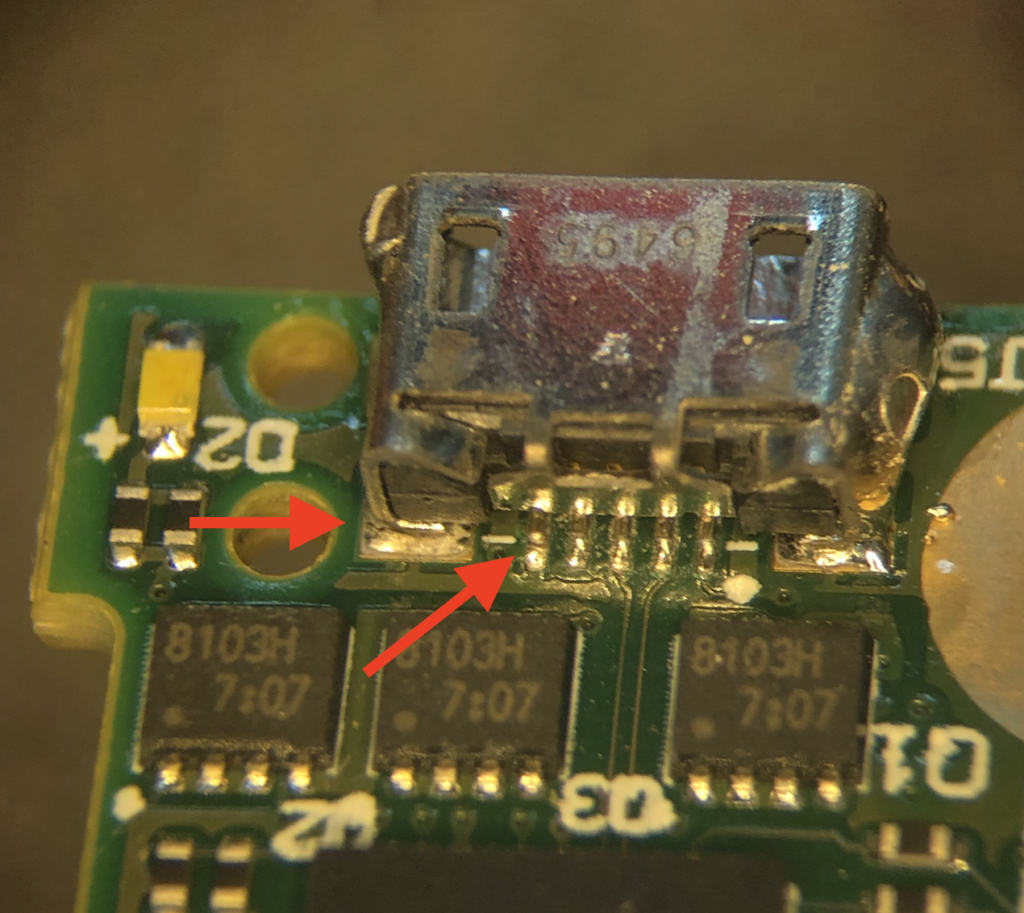

To be fair, there is a plastic block holding the USB-connector down, but mechanically that doesn’t do much. A proper design of the connector’s PCB footprint might have saved this specimen though.

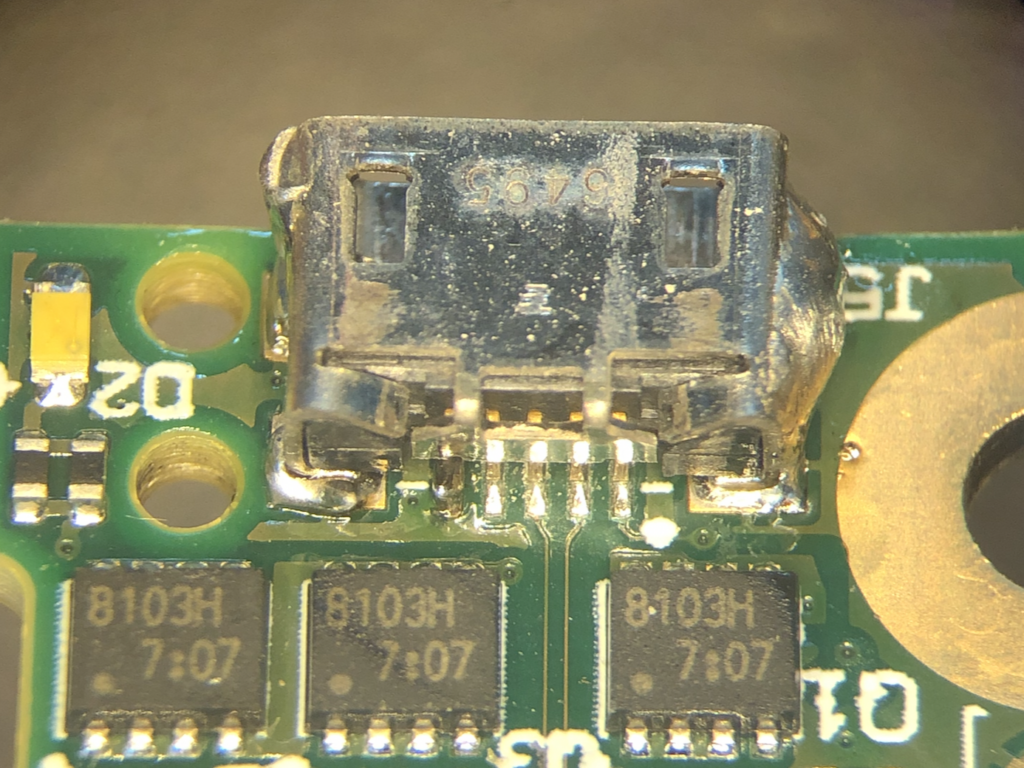

Under a microscope, cracks in the soldering of the connector are clearly visible. There’s a nice power LED (D2) next to the connector. Let’s get those cracks fixed up and power it up.

Insert power – “pop”! But no light. Hmmm. Maybe the seller lied about it working intermittently? Was it maybe fried altogether? Check all IC’s for visual damage or magic smoke – nothing. No smell either.

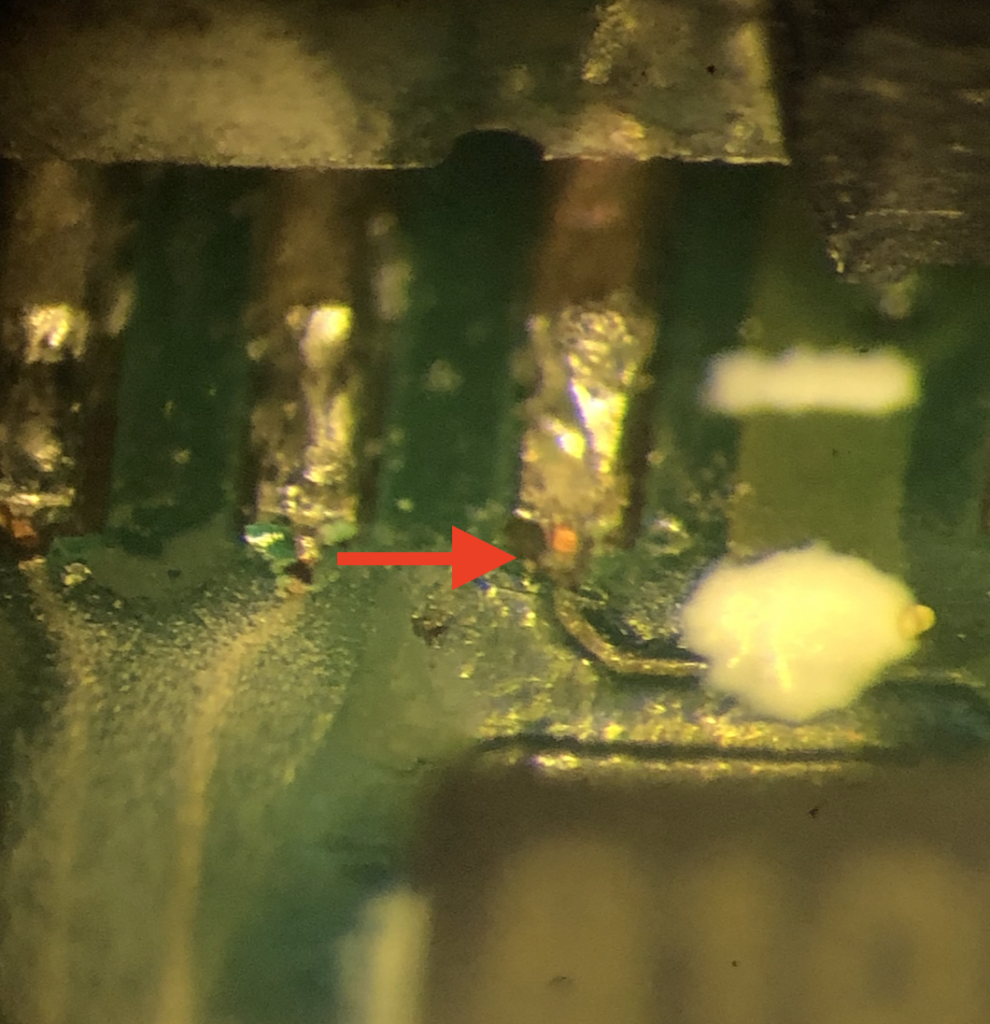

Turned out that the “pop”-sound was made by something else completely unrelated. Look closely at the rightmost pin on the connector (next to the white dot – VCC or +5v). Looks good, right?

Turns out that the power for this thing runs through a *tiny* (4mil?) trace which also had been severed clean when the force was applied. Very hard to spot, even under a professional stereo microscope with proper lighting (and experience).

If you use BMD products (or any devices with micro USB or similarly flimsy connectors) in a rough environment, secure down the cable (e.g. with gaffer tape) near the connector. This way, pulling the cable doesn’t disconnect or break the connector.

One more step could be to put blocks of wood, LEGO or similar material around the connector to create a ‘hole’ for the connector to live in, so any snagging, pulling or falls strains the block in stead of the connector.dwdew

If you’re a device designer, PCB layouter, product architect or in any similar position to do something about this during design or scoping of the project – do so. Millions of devices end up in landfill because of simple problems like this – while the world is quite literally on fire.

I’ve fixed tens (maybe a hundred?) devices with this problem. Usually, the time-cost doesn’t match the value of the item (hello Chinese disco-light!). BMD is by no means the only company not doing this right.

Some Tips:

Keep in mind: Circuit board, thin copper traces and solder are all very brittle – meaning there is little displacement required for the mechanical and electrical connections to get separated. Even a tiny tolerance or play (e.g. on a bracket) of say 0,2mm might be enough to reach ‘yield’ conditions in any of those. Make sure they can’t be reached (with a safety margin). That’s why the plastic block holding down the USB-connector inside this product is a non-working afterthought.

Yes this adds costs. But these are tiny in comparison to the cost of products failing, (film) productions halted or delayed, and the damage to your brand’s reputation. The environment (and your users, co-workers in warranty, stock holders etc. etc.) will thank you.